Stainless steel and aluminum (aluminum) are versatile materials with their unique advantages. Here are some of the advantages of stainless steel compared to aluminum:

- Corrosion Resistance: Stainless steel is highly resistant to corrosion and rust, especially when exposed to harsh environments, chemicals and moisture. It maintains its structural integrity and appearance even under difficult conditions, making it suitable for exterior and marine applications. Aluminum, while resistant to corrosion, requires additional protective coatings or anodizing to achieve a similar level of corrosion resistance.

- Strength and Durability: Stainless steel is known for its exceptional strength and durability. It is a robust material that can withstand high loads, impacts and harsh working conditions. It is often preferred in applications requiring structural integrity and durability, while aluminum is relatively softer and less strong than stainless steel.

- Heat resistance: Stainless steel has excellent resistance to high temperatures, making it suitable for hot applications such as B. Exhaust systems of motor vehicles, industrial furnaces and fireplaces. Aluminum has a lower melting point and is not as heat resistant as stainless steel.

- Aesthetic Versatility: Stainless steel offers a wide range of finishes including brushed, polished, satin and textured options. It has a timeless and sophisticated appearance that adds a touch of elegance to various designs. While aluminum also comes in a variety of finishes, it may not offer the same level of aesthetic versatility and may be more associated with a modern or industrial look.

- Sanitation and Hygiene: Stainless steel is a preferred choice in industries that require strict hygiene standards, such as B. in food processing, healthcare and pharmaceutical industries. It is non-porous, easy to clean and resistant to bacterial growth. While aluminum is relatively easy to clean, it may not have the same hygienic qualities as stainless steel.

- Recyclability: Both stainless steel and aluminum are highly recyclable. However, stainless steel retains its properties throughout the recycling process, making it a more sustainable choice in terms of long-term recyclability.

Ultimately, the choice between stainless steel and aluminum depends on the application at hand, taking into account factors such as corrosion resistance, strength requirements, heat resistance, aesthetics and hygiene considerations. Stainless steel is often preferred for its superior corrosion resistance, strength, heat resistance, and versatility in demanding applications, while aluminum is noted for its light weight and ease of formability.

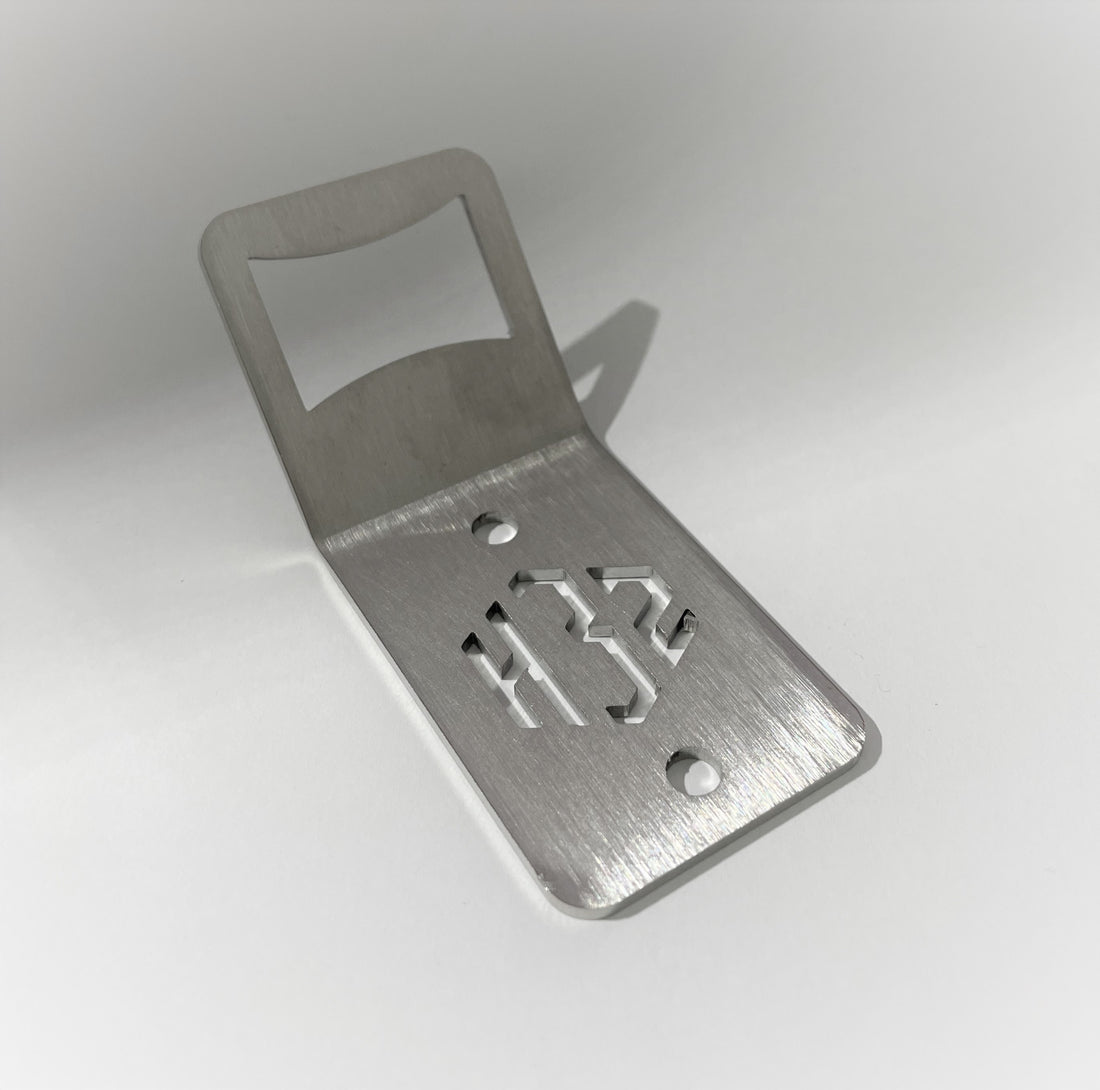

It is precisely for these reasons that we use both materials at H32.

In order to keep the weight of our products as low as possible, we use aluminum for the large components and compensate for the lack of strength with a well thought-out construction.

Wherever stability is more important than the weight of the respective component, we use stainless steel. (partly blank but also powder-coated)

Example:

- steps

- anti-theft device

- logo plate

- bottle opener

Our assembly material (screws) is exclusively made of stainless steel!